Find the best Order Fulfillment Software

Compare Products

Showing 1 - 20 of 214 products

Sort by

Reviews: Sorts listings by the number of user reviews we have published, greatest to least.

Sponsored: Sorts listings by software vendors running active bidding campaigns, from the highest to lowest bid. Vendors who have paid for placement have a ‘Visit Website’ button, whereas unpaid vendors have a ‘Learn More’ button.

Avg Rating: Sorts listings by overall star rating based on user reviews, highest to lowest.

A to Z: Sorts listings by product name from A to Z.

Shipedge

Shipedge

The Shipedge Platform was created to solve the challenges associated with the complete order management lifecycle and supporting activities. We’re dedicated to providing innovative solutions to make commerce easier and more connec...Read more about Shipedge

Excalibur WMS

Excalibur WMS

Excalibur WMS by Camelot 3PL is a cloud-based or on-premise warehouse management solution (WMS), designed exclusively for third-party logistics (3PL) warehouses and fulfillment operations. Excalibur is customizable for a variety o...Read more about Excalibur WMS

NetSuite

NetSuite

With an integrated system that includes ERP, financials, commerce, inventory management, HR, PSA, supply chain management, CRM and more – NetSuite enables fast-growing businesses across all industries to work more effectively by a...Read more about NetSuite

WithoutWire

WithoutWire

The WithoutWire Inventory Platform WMS is built for complex inventory management. With one mobile app that can be deployed across iOS and Android platforms, rugged or consumer devices, our Inventory Platform WMS is easy to integra...Read more about WithoutWire

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Meet Eric, a software expert who has helped 1,534 companies select the right product for their needs.

Talk with us for a free

15-minute consultationSoftware Advice is free because vendors pay us when they receive sales opportunities.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

This allows us to provide comprehensive software lists and an advisor service at no cost to you.

Tell us more about your business and an advisor will reach out with a list of software recommendations customized for your specific needs.

STEP 1 OF 4

How many employees are in your company?

Kechie

Kechie

Kechie Distribution Management efficiently manages internal and external resources. Suited for growing businesses, the management tools provide control of replenishment, warehouse management, pick, pack, and ship, procurement, pro...Read more about Kechie

VeraCore

VeraCore

The VeraCore Fulfillment Solution was developed for leading 3PLs, order fulfillment companies, and online retailers. VeraCore is designed to be at the core of your fulfillment business. More than just pick & pack software, VeraCo...Read more about VeraCore

SOLOCHAIN WMS

SOLOCHAIN WMS

SOLOCHAIN WMS is a highly flexible and adaptive warehouse management system built for companies that need their supply chains to be nimble, efficient, and scaling, while ensuring execution excellence, compliance, and operational s...Read more about SOLOCHAIN WMS

SAP S/4HANA Cloud

SAP S/4HANA Cloud

SAP S/4HANA Cloud is a cloud-based and on-premise enterprise resource planning (ERP) solution. It is suitable for small, midsize and large businesses in industries such as automotive, engineering, construction, mining, research an...Read more about SAP S/4HANA Cloud

Agiliron

Agiliron

Agiliron is an all-in-one Retail Management System which allows you to manage all orders, inventory and CRM records, from all channels, in one place. Agiliron also integrates with many of your existing business tools like Quickb...Read more about Agiliron

Easy WMS

Easy WMS

Mecalux Easy WMS is a warehouse management solution that helps e-commerce manufacturers, distributors, and third-party logistics businesses automate the entire supply chain lifecycle, from order management to shipping. It enables ...Read more about Easy WMS

Oracle Fusion Cloud SCM

Oracle Fusion Cloud SCM

Oracle Supply Chain Management (SCM) With Oracle Supply Chain Management (SCM) & Manufacturing, organizations can respond quickly to changing demand, supply, and market conditions. Seamlessly connect your supply chain to create a...Read more about Oracle Fusion Cloud SCM

Trimble TMS

Trimble TMS

Trimble TMS solutions help carrier companies keep their costs and services competitive, while delivering significant value every day. Trimble’s TMS products helps businesses with fleet management, route optimization, dispatch, loa...Read more about Trimble TMS

ShipHawk

ShipHawk

At ShipHawk, we’re dedicated to improving and automating the world behind the buy button for growing companies. The reality today is that independent businesses must deliver on expectations set by the mega-retail giants and they h...Read more about ShipHawk

Da Vinci Supply Chain Business Suite

Da Vinci Supply Chain Business Suite

Da Vinci is a cloud-based supply chain management (SCM) solution designed specifically for 3PLs, internet retailers and wholesale businesses with demanding warehouse, fulfillment and transportation needs. In addition to a WMS an...Read more about Da Vinci Supply Chain Business Suite

proVision WMS

proVision WMS

Ahearn &Soper Inc. is a leading provider of supply chain technology to the warehouse, manufacturing, and healthcare industries throughout North America. The company’s portfolio includes software, hardware, supplies, and service. O...Read more about proVision WMS

Warehouse Management System

Warehouse Management System

Geneva Systems offers both an on-premises installation or a hosted installation for full access via the Internet. Multi-Language support allows users to switch between languages on the fly for their international business activiti...Read more about Warehouse Management System

Coupa

Coupa

Point solutions are pointless: spend smarter with the leading spend management platform built for companies like you. The Coupa platform allows you to take control of your spend and position your business for resilience and growth...Read more about Coupa

Logiwa WMS

Logiwa WMS

Logiwa WMS is a cloud-based warehouse management and order fulfillment solution built on a .NET framework. The solution supports disparate warehousing processes, separate product groups and the needs of different sectors within a ...Read more about Logiwa WMS

iM3 SCM Suite

iM3 SCM Suite

iM3 SCM’s Smart Warehouse Management (smartWMS) is a cloud-based software offered to its customers as a SaaS Application. iM3 SCM helps clients reduce their implementation costs to help increase ROI and productivity. From mul...Read more about iM3 SCM Suite

Ramp Enterprise WMS

Ramp Enterprise WMS

Enterprise WMS and Interchange EDI by Ramp Systems is a warehouse management system (WMS) that provides tools for both asset-based and non-asset-based 3rd party logistics (3PL) companies. The software has a report writer feature t...Read more about Ramp Enterprise WMS

Popular Comparisons

Buyers Guide

Last Updated: March 16, 2023Here's what we'll cover:

What Is Order Fulfillment Software?

Common Features of Order Fulfillment Software

Evaluating Order Fulfillment Software

What Is Order Fulfillment Software?

An order fulfillment system automates the order fulfillment process, from order entry to delivery, ensuring that a production order is completed with the highest level of accuracy and least amount of lead time necessary. It promises high quote accuracy, fulfillment efficiency and billing management tools to maximize billing and order effectiveness. It is often combined with transportation management software and warehouse management software to create a supply chain execution system that promises real-time visibility.

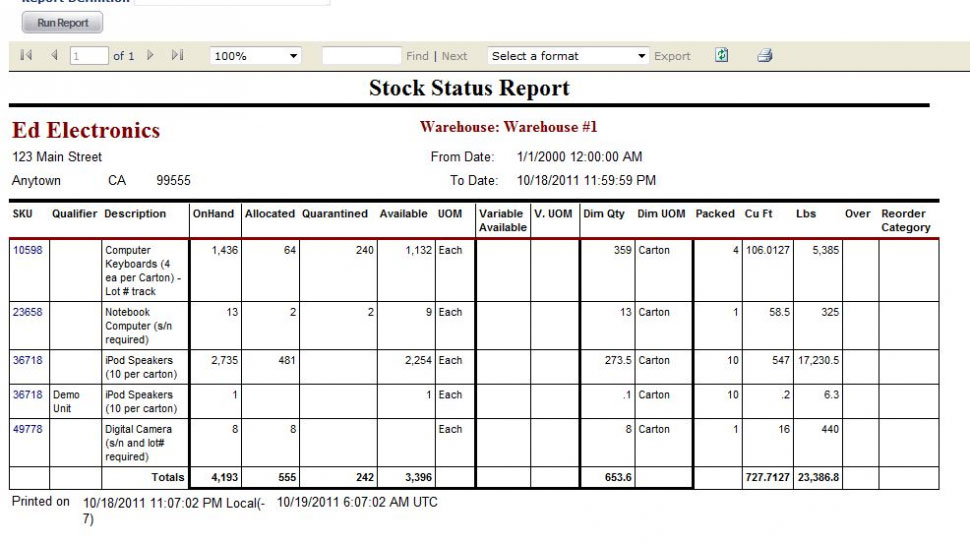

Inventory reports in 3PL Warehouse Manager

Common Features of Order Fulfillment Software

Order fulfillment starts with a smooth quote-to-order-to-cash transition, so the user can deliver a quote to the buyer that is both accurate and achievable, the implication being that customers expect no deviation from the original quote provided to them by the supplier.

Once the quote offer has been accepted, the next step is order fulfillment, which comes with four potential degrees of flexibility:

Made-to-stock (MTS) or build-to-forecast (BTF) | This option is for products that are mass produced in anticipation of future demand and will be used by vendors whose products are in constant demand and never customized. The software would likely suggest recurring billing cycles to meet ongoing sales and purchase needs. |

Build-to-order (BTO) or make-to-order (MTO) | BTO or MTO software is for standardized products that are produced only when ordered, but are never customized in the building process. This requires project-based billing, but simple efficiency, rather than customizability in the ordering process. |

Assemble-to-order (ATO) | The ATO option is for products that are assembled to order from a select number of possible components. ATO allows only as much customization as the available components can deliver, providing the minimum amount of flexibility required in this situation. |

Engineer-to-order (ETO) | The most customizable option, ETO gives the customer more control over the design of the product by engineering production to the customer’s needs. Order fulfillment software would likely assign time-based billing to ETO products and allow much greater overall functionality to meet the required customization. |

Finally, order processing software handles financial transactions through billing management, which prevents billing errors that would otherwise interrupt cash flow. The important thing for suppliers is to limit days sales outstanding (DSO) and obtain real revenue from customers. In this case, order fulfillment systems use accrued or deferred revenue recognition processes to keep track of accounts receivable and which customers have paid for products and services rendered.

Order fulfillment itself is often included as functionality within a slightly-broader order management system.

Evaluating Order Fulfillment Software

Obviously, the type of product(s) and degree of customization required will be the biggest deciding factor in evaluating order fulfillment software. A close second will be quoting billing needs, since quote accuracy and billing cycle requirements are such a key component of order fulfillment.

Consider the following when selecting an order fulfillment software vendor:

Are price quotes a major part of your ordering/fulfillment needs?

To what degree are products manufactured and/or customized to order?

Do you need time-based billing?

Do you mass-produce products in anticipation of future demand?

Market Trends to Understand

Over the past couple of years, there has been increased focus on improving order fulfillment by making the supply chain more efficient. Technological advancements can help companies achieve customer satisfaction with faster processes and ultimately, deliveries.

Here are a few market trends that buyers should keep in mind:

E-fulfillment of orders in the future. Improved channels of shopping for customers means that businesses will ensure faster shipments, accurately predict which products will be popular at what time and increased loyalty from customers.

Mobile devices to check up on orders. Mobile apps have been successful in enhancing the shopping experience. Therefore, many retailers are using mobile apps in their physical and/or online stores. Apps help them promote new products and inform customers about sales. The customer experience is further boosted through heavy discounts and coupons that are redeemable only on the mobile apps. This drives up the usage of the app.

More accurate predictions of seasonal demand and sales. The use of big data and analytics to gauge seasonal demand and sales has resulted in near-accurate predictions. Retailers are using this data to make sure that the staff are trained, inventories stocked, delivery schedules finalized and processes synchronized to ensure smooth operation before the demand soars.

Technology can help to improve operations. Businesses, especially e-commerce companies, track and manage their supplies, volume and transportation using their mobile devices and PCs. These tools have sped up the processes across the supply chain. The adoption of cloud-based software has also helped retailers and suppliers gather data to make business decisions. As cloud security improves, more businesses are expected to adopt cloud solutions.

Expanding warehouses will enable shipping of large items. Over the past few years, the boom in e-commerce has led to increased sales of larger items as well. To meet this demand, businesses need to expand the sizes of their warehouses and anticipate backup options for storage. They also need to utilize local fulfillment centers for faster deliveries, thus, increasing their competitiveness in the market.

Globalization helps to accommodate international demand. With market boundaries transcending national boundaries, international demand will drive speedy deliveries in the order fulfillment industry. Sellers and buyers in different corners of the globe can conduct business without worrying about exaggerated shipping and delivery charges. Various e-commerce companies will offer products from different countries, making it possible for customers to access international markets from the comfort of their homes. The order fulfillment solution should be able to deal with multiple currencies and allow digital payments, such as Bitcoin, so that small players can fairly compete with the bigger, international players.

Inventory should be managed in real time. Supply chains are expected to introduce technology, such as beacons and sensors, to quicken checkouts and restocking. Businesses will need solutions that automatically track on-shelf supplies, restocking, reordering and even manufacturing in real time on a regular basis.

Environment-friendly measures will increase sustainability. Businesses need to have minimal impact on the environment to be sustainable in the long run. They need to adopt green processes that reduce and prevent wastage. They can use order fulfillment software to change their delivery and sourcing practices and become environment friendly.